ECO-CH-202110L

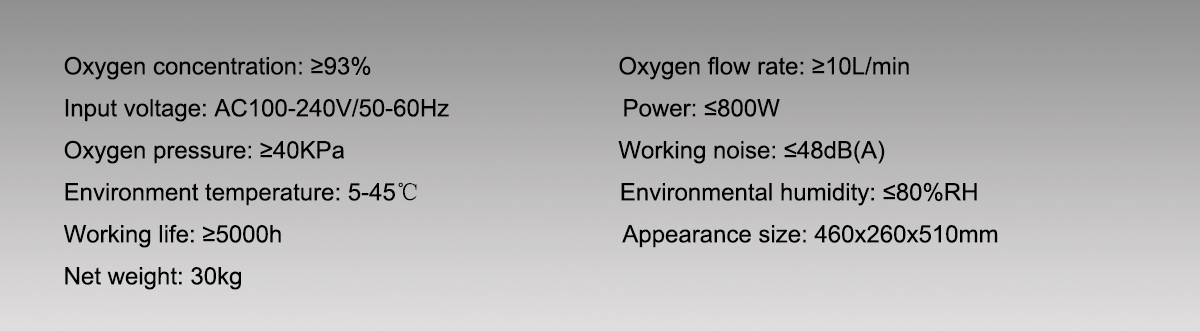

AC100-240V

≤800W

≥10L/min

--㎡

CE

• The oxygen machine consists of an air inlet filter, a water filter, a dryer, a drain valve,

an oxygen adsorption tower, a gas collecting tank, a solenoid valve, an electric control board,

It is also composed of an oxygen pressure regulating valve and an oxygen flow meter.

• Double-row condensing radiators and powerful cooling fans are used,

and the high-temperature compressed air from the compressor can be fully reduced to

the dew point temperature.

The moisture in the compressed air instantly forms dew drops.

• Adopting water filter and dryer as double water filtration solution, and the water is

automatically drained every 3mins, which can fully filter the moisture of the compressed

air and greatly extend the service life of molecular sieve, so this oxygen maker can be

used in a wide range of areas.

• Adopting the bottom heat dissipation method, and spray the water separated from

the water filter to the top of the compressor as an auxiliary cooling function.

When running continuously, the whole machine is not hot.

• Using lithium molecular sieve material, stable and reliable work.

• The whole machine is manufactured according to the standard of medical oxygen generator,

with high oxygen concentration, low machine vibration and low noise.

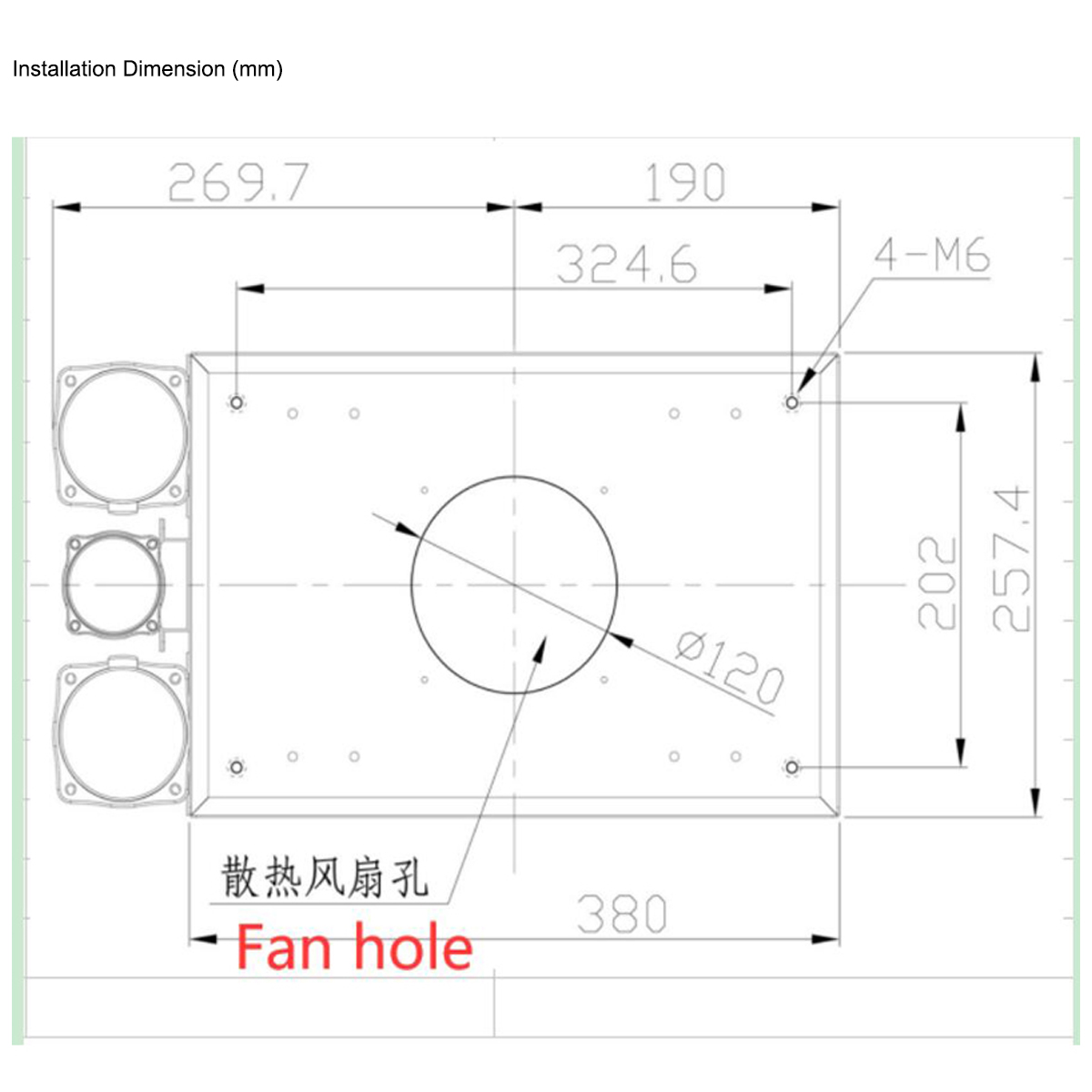

If you need to fix the oxygen unit in an machine, please do the followings:

1. Create the fan cooling holes (≥φ120mm) and 4 screw holes (φ6.2~φ6.5mm) according to the installation dimensions of the attached drawings;

2. Remove the 4 rubber feet at the bottom;

3. Use 4pcs M6 screws to fix on the nuts inside the oxygen machine. The 4pcs M6 nuts are welded to the inner wall of the bottom of the machine. Spring washers are required. The length of the screws is recommended. M6*25, should not exceed M6*40.